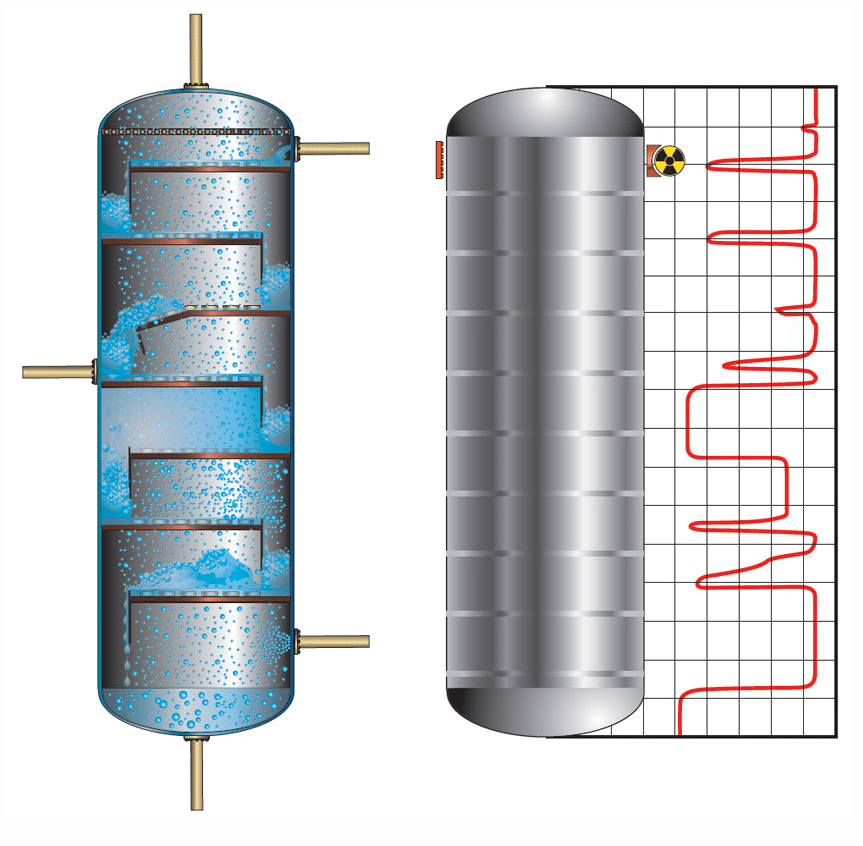

ScanTech uses gamma ray technology to detect a wide range of issues in packed trays, towers, and other equipment. By using this technology to peer inside of the mechanisms, we can gain insight into the nature of the issues inside without having to use invasive methods. There are a number of problems that can lead to loss of efficiency and even to malfunction, so making sure you detect issues early is important. Here are a few of the problems that our gamma scans can detect.

Tray damage

Column internals need to be assessed without being able to see them. A gamma scan can read the relative height of liquid in the trays and returns a reading. A tray or a few trays cannot maintain an adequate froth because they are damaged, then we can see this in our readings.

Flooding

Mechanical issues can often lead to a restriction in liquid flow in the column that can cause flooding. A gamma scan can quickly and seamlessly detect whether or not there is flooding and to what extent it has affected the column. We can even help determine the cause.

Weeping

When liquid rains down from tray to tray, it almost looks like the column is crying. That’s where we get the term weeping. Weeping is usually caused by mechanical damage or poor design. Using a gamma scan, we can determine if weeping is occurring and how severe your case is.

Foaming

Foaming is one of the most common problems that we treat, and is one of the easier problems to detect. Our scans can quickly determine if there are hitches above the liquid in the trays. Once we determine that you have a case of foaming, we recommend a follow up scan to determine the effectiveness of your anti-foaming treatments.

ScanTech is the best in the business at what we do, and we’ve grown to provide services around the world. Gamma scans are one of our core services, and can be used to detect a wide range of issues. These are the problems that gamma scans can detect.

If you think that you are experiencing any of them, contact us today.

Leave A Comment

You must be logged in to post a comment.