Industrial CT Scanning Services

ScanTech’s industrial CT scan service offers enhanced visualization through industrial computed tomography. This procedure provides a comprehensive 2-Dimensional view, covering 360 degrees of the vessel at a specific height or location.

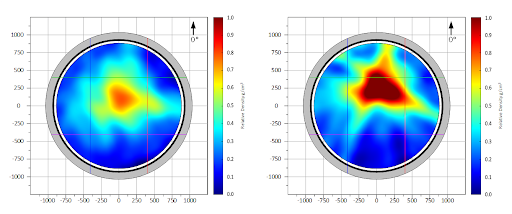

The result is a detailed, color-coded density map of the interior of the vessel or pipe, delivering precise insights into its internal structure and composition.

The CT Scan, a specialized service, complements the gamma scan on packed towers and is instrumental in detecting annular maldistribution. Selection of CT scan locations is informed by the outcomes of the preceding Gamma Scan tests.

When applied to piping, the CT scan unveils density variations, especially when different liquids and gasses experience laminar flow or during fluctuations in overall density within 2-phase flow. Furthermore, it offers insights into deposit patterns within the pipe’s interior at specific locations.

Industrial CT Scanning Procedure

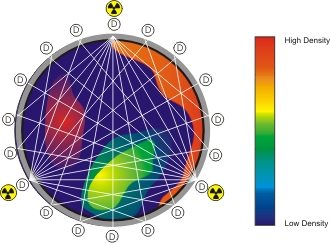

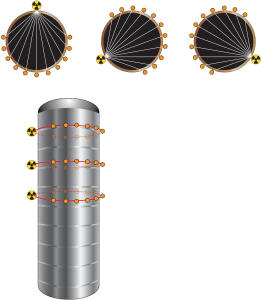

CT scans involve placing an array of detectors at a specific elevation on the exterior of the vessel. Simultaneously, a gamma radiation source is positioned on the opposite side, enabling the capture of density readings at each detector’s location.

To ensure a comprehensive view, the source and detector network is systematically rotated through specific angles, with density readings taken at each position. This rotation is repeated at various angles until the CT scanner completes a full 360-degree scan around the vessel.

Following data collection, our specialized software processes the CT imaging data, producing a detailed 2D density image of the vessel’s interior. The resolution of this density map depends on the number of samples obtained during the CT scan procedure.

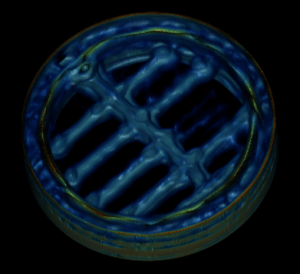

For additional scans at different elevations, the equipment can be repositioned, and the process is repeated to capture a comprehensive picture of the vessel’s internal structures and composition. Small positional increments may be used to create a 3D density image for enhanced analysis if the vessel structure allows for acquisition.

Equipment We Monitor

At ScanTech, we’re your trusted partner for industrial CT services that reach far beyond the ordinary. Our specialized computed tomography (CT) scan service is tailored to meet your unique needs, including:

- Packed Tower Maldistribution: We have the expertise to uncover and rectify maldistribution issues within packed towers, ensuring efficient and consistent performance.

- Solid and Liquid Identification in Pipelines: With our advanced technology, we can precisely identify and differentiate between solids and liquids within pipelines, a crucial aspect of maintaining operational integrity.

- FCCU Riser Catalyst Distribution: Our CT scanning service extends to FCCU riser catalyst distribution, ensuring that catalysts are evenly and optimally distributed for improved efficiency.

- Profiling Tower Internals: We delve deep into the intricacies of towers, including distributors, demisters, and trays, providing you with detailed insights to optimize your operations.

With ScanTech’s expertise and advanced CT scanning technology, you gain the upper hand in quality control, safety, and performance optimization.

Requirements

ScanTech’s specialized CT scan service is designed to cater to our customers’ specific needs, offering the following benefits:

- Accessibility at various scan heights

- Comprehensive access around vessels

- Capability to accommodate a wide range of diameters, from small to large

- Examination of internal components or packing structures

- Application to both vessels and piping

ScanTech’s cutting-edge CT technology is your gateway to precision and reliability. Our services go beyond conventional diagnostics, enabling in-depth analysis that is instrumental in ensuring the integrity of your critical components.

Whether it’s identifying hidden defects, analyzing complex internal structures, or inspecting pipelines and vessels, our CT services provide a 360-degree view, offering a comprehensive understanding of your assets. Trust ScanTech for unmatched accuracy and insights that empower your quality control and maintenance efforts.